1 Department of Management, Sinhgad Institute of Business Management (SIBM), Mumbai, Maharashtra, India

2 Department of Sustainability Management, Indian Institute of Management (IIM), Mumbai, Maharashtra, India

3 Department of Operations Management and Quantitative Techniques, International Management Institute (IMI), Chandaka Malipada, Bhubaneswar, India

4 Department of Marketing and International Business, K J Somaiya Institute of Management, Mumbai, Maharashtra, India

5Imperial College of Engineering and Research, Pune, Maharashtra, India

6 Department of Business Studies, Central University of Karnataka, Kalaburagi, Karnataka, India

Creative Commons Non Commercial CC BY-NC: This article is distributed under the terms of the Creative Commons Attribution-NonCommercial 4.0 License (http://www.creativecommons.org/licenses/by-nc/4.0/) which permits non-Commercial use, reproduction and distribution of the work without further permission provided the original work is attributed.

Green supply chain management (GSCM) has been proposed as a potential remedy for business sustainability-related issues. This study offers key green practices that may be applied at the strategic, operational and tactical levels in order to combine conventional supply networks with sustainable supply chains. When establishing the criteria, professional opinions were taken into account in order to identify pertinent components. The analytic hierarchy process has been used to assess the relative weights and relevance of the GSCM criteria. The expert opinions from academic and industrial specialists were used to make pair-wise comparisons. Green practices have been prioritised, and a framework with 4 major factors and 16 sub-factors has been proposed for making intelligent judgements. Findings point out that top leadership commitment to sustainability-related issues, legal compliance, environmentally friendly design, green purchasing, health and safety, and regulatory compliance practices are crucial for implementing sustainability across the supply chain. It might be claimed that adopting GSCM practices can boost a company’s long-term performance while also increasing its operational eco-efficiency reaping cost and efficiency benefits. The results of the study would assist GSCM practitioners in selecting appropriate strategies in consonance with the governing rules and regulations and customers’ requirements.

Green supply chain management, environmental factors, social factors, analytic hierarchy process, strategic initiatives

Introduction

In the highly competitive economic climate of today, corporations cannot afford to disregard environmental problems. Green concerns now have a prominent position in industrial companies’ strategic planning agendas as a result of increased government restrictions and higher public demands for environmental accountability. Further, due to increasing outsourcing in several sectors and rising globalisation, business today operates and competes on a supply chain (Abdallah & Al-Ghwayeen, 2020; Beamon, 1999; Gawusu et al., 2022; Haiyun et al., 2021; Micheli et al., 2020; Roh et al., 2022). This predicament has resulted in a supply chain that is resource-intensive, extractive and long-term unsustainable. A crucial tactic for companies striving to become environmentally sustainable recently emerged as the integration of social and environmental aspects into supply chain management. The combination of supply chain management and environmental management has only lately started to be referred to as ‘green supply chain management’ (GSCM). The importance of GSCM is rising for many firms as ‘green’ concerns are pushed by consumers and regulatory frameworks (Assumpção et al., 2022; Haiyun et al., 2021; Ilyas et al., 2020; Lee, 2008; Luthra et al., 2014a, 2014b). It is a concept that is gaining traction due to its dedication to corporate and business sustainability (de Oliveira et al., 2018; Micheli et al., 2020). It is viewed as a method for improving economic performance and competitive advantage while simultaneously lowering the use of chemicals and hazardous materials, energy usage, waste generation and pollution (Gawusu et al., 2022; Tumpa et al., 2019). Thus, in businesses worldwide, GSCM practices are gradually becoming a primary strategic focus and a crucial component of corporate strategy (Abdallah & Al-Ghwayeen, 2020).

Strategic planning in the context of GSCM refers to the identification of relevant goals and the design of long-term management strategies for those goals. GSCM is viewed as an effective approach for companies to achieve profit and market share goals since it lowers their environmental risks and repercussions while enhancing their ecological efficiency (Kumar et al., 2012). Selecting the right green practices is one of the most important phases in integrating environmental practices into a conventional supply chain (Hsu et al., 2013; Ilyas et al., 2020; Tumpa et al., 2019). The linkage between business performance, supply chain strategy and environmental strategy was investigated by Wu et al. (2012). To improve business success, they recommended that supply chain and corporate environmental initiatives be coordinated. Thus, decision-makers in supply chains are responsible for creating sustainability orientations for reducing liabilities based on numerous considerations related to economic, environmental and social concerns.

Of late, businesses have started to recognise the need of putting environmental sustainability policies into practice due to growing regulatory, competitive and marketing constraints (Roh et al., 2022; Tumpa et al., 2019). Even while neutrality is presently sought only against external stakeholders and not against enterprises' internal greening activities, the role of environmental concerns in competitive strategy is still viewed as neutral. Businesses engage in green improvement programmes because they want to match up with rival businesses or meet the demands of consumers, regulators, investors, interest groups and the local community. Manufacturing businesses must implement green strategies as society grows more environmentally conscious and concerned, if they are to fulfil their objectives effectively and economically. Green practices must be used in order to open up opportunities for sustainability in order to handle the growing sustainability concerns. Understanding the several green features that might help firms align sustainability in a supply chain context is crucial. The identification of projects that may be used to achieve the triple bottom line (economic, environmental and social) goals of the organisation is crucial for the effective implementation of sustainability in a supply chain. Therefore, this paper aims to understand

(i) The key green practices for introducing sustainability interventions in a supply chain.

(ii) Introducing a framework through a construct design based on the analytic hierarchy process (AHP) on achieving the performance on the triple bottom line.

(iii) To recognise and rank the key strategies that help to achieve an effective adoption and implementation of GSCM.

With these considerations in mind, this research suggests using AHP, an multi-criteria decision making (MCDM) approach, to assess the various GSCM criteria. The article presents and proposes a thorough methodology for implementing GSCM. It assesses environmentally friendly supply chain management strategies through a comparative study including a sample of industries. Four main constructs are the centre of the theoretical framework encompassing the organisational commitment, business operations, social aspect and environmental aspect.

The rest of the paper is structured as follows. The second section examines the relevant literature on GSCM practices, which provides a foundation for identifying significant GSCM elements and implementation methodologies. The third section describes the research framework and methodology. The fourth section covers the results and discussion. The conclusions of the study and the limitations are discussed in the final parts, along with some recommendations for the scope and direction of future research on the subject.

Literature Review

In an organisation, sustainability interventions may be made in a variety of ways, from the early phases of policy creation through their implementation in regular company operations. Organisational commitment to environmental and social considerations is one cutting-edge green practice in coordinating supply chain operations towards a greener supply chain. Hoejmose et al. (2012) assert that senior management support is one of the factors that act as a strategic facilitator to sustainability initiatives, making it essential to engage in strategic thinking on sustainability-related objectives to move towards greening endeavours. Top management leadership and their commitment to the risks connected with sustainability, environmental compliances, policy and planning may be advantageous for organisations that are focused on sustainability. It is also cited as being essential for combining sustainable practices with business operations (Assumpção et al., 2022; Gawusu et al., 2022; Haiyun et al., 2021; Handfield et al., 2002; Lee, 2008; Micheli et al., 2020). Green supply chain (GSC) practices that are integrated into multiple business process segments result in a coordinated GSC. According to Sarkis et al. (2011), GSCM refers to the interorganisational practices of sustainable supply chain management including reverse logistics. Despite differences in definitions, a number of commonly used terms are still used to characterise GSCM, such as ‘green purchasing and procurement’ (Min & Galle, 2001), ‘green logistics and environmental logistics’ (Murphy & Poist, 2003), ‘supply chain environmental management’ (Sharfman et al., 2009) and ‘sustainable supply network management’ (Assumpção et al., 2022; Ilyas et al., 2020; Yuang & Kielkiewicz-Yuang, 2001).

Environmental rules are considered to be yet another essential instrument that may help raise environmental performance while attempting to comply with legal requirements (Abdallah & Al-Ghwayeen, 2020; Ilyas et al., 2020; Lee et al., 2009). Businesses are encouraged to adopt GSCM practices by government rules and legislation (Drohomeretski et al., 2014; Mudgal et al., 2010; Tumpa et al., 2019). Regulation-compliant environmental standards can promote industry competition, increase profitability and improve environmental performance (Gawusu et al., 2022; Green et al., 2012). The necessity for organisations to boost operational effectiveness in order to satisfy environmental regulations may also boost the firm's competitiveness. Green practices are considered crucial for integrating sustainability into core business processes, which over time can have benefits such as cost and risk reduction (Roh et al., 2022; Zhu & Sarkis, 2004; Zhu et al., 2010). Green production methods including optimum resource utilisation (water, energy and raw materials), the use of non-hazardous materials, recyclable goods and compact designs with enhanced functionality are included in manufacturing as well as design for the environment (DfE) practices at the product design stage. Chiou et al. (2011) and Zhu et al. (2007) discussed initiatives such as design for greener items and greener processes in order to increase the profitability and efficiency of production. A crucial industry for implementing sustainable practices, according to research, is logistics. By using recyclable packaging materials, reducing the need for packing and employing routing software to speed up logistics, a company's environmental footprint at the distribution stage of the supply chain may be greatly decreased (Assumpção et al., 2022; Meera & Chitramani, 2014; Roh et al., 2022;). Purchasing raw materials or components from ‘Green Partners’ that fulfil green partner environmental quality requirements and pass an audit method in ISO14000, OHSAS18000 and/or RoHS laws is one of the practices for sustainable procurement (Guang Shi et al., 2012; Ilyas et al., 2020). Reduced material use, closed-loop production and the use of inputs with relatively less negative environmental effects are some of the other operations-related interventions (Abdallah & Al-Ghwayeen, 2020; Thun & Müller, 2010). Thus, environmental standards and certifications may be just as important as environmental legislation in helping to implement sustainable solutions.

Dubey et al. (2015a, 2015b) recognised social sustainability as a driving element for GSCM together with environmental interventions, notably with respect to ethics, working conditions, human rights, safety and community participation. Social responsibility is becoming a key component of creating a global competitive advantage. Businesses are proving their dedication to environmentally friendly practices as a result of growing public concern and awareness for such practices (Fahimnia et al., 2015a, 2015b; Seuring & Müller, 2008; Srivastava, 2007). Greener goods are being developed by manufacturers to meet customer demand and stay competitive in the market. According to Seuring and Müller (2008), stakeholders including clients, investors, regulators and non-governmental organisations (NGOs) are increasingly pressurising businesses to change the way they do business. The need for sustainable or GSCM has increased as a result of these factors. Thus, it is essential to map the whole supply chain and include environmental management capabilities in a conventional supply chain through prioritisation.

Organisational environmental policies developed by management and a supportive organisational culture towards GSC initiatives are the key facilitators of GSC management practices (GSCMP) implementation (Luthra et al., 2014a, 2014b; Micheli et al., 2020). Lower operating costs, more efficiency and improved brand awareness etc. are the primary factors or motivators for a supply chain to go green. However, the practitioners are not yet prepared to use GSCMP across the board. The lack of environmental consideration and strategies is viewed as a major impediment to GSCMP implementation. This can be attributed to the non-availability and access to comprehensive and simple-to-use tools for evaluating the environmental performance of green materials. Further, the lack of expertise of industry practitioners in adopting GSCMP increases the initial cost of GSC programmes that may act as a hindrance. This eventually leads to the tendency to exaggerate the extra expense associated with GSCMP projects. Further, the implementation of GSCMP will be negatively impacted by industry personnel's false perceptions of their environmental duties. Experts and administrative members who are unaware or ignorant of environmental issues and concerns also hinder GSCMP efforts and the espousal of sustainable practices and the growth of green industries (Al Zaabi et al., 2013). Without collaboration amongst all business departments, GSC efforts cannot be executed successfully (Abdallah & Al-Ghwayeen, 2020; Luthra et al., 2016). Employing green materials can occasionally be uncomfortable, which discourages practitioners from putting GSCMP into practice. Several industries are not interested in a GSC because green products perform poorly in terms of cost–benefit and compatibility. Moreover, the absence of required ecologically friendly items might substantially discourage businesses from implementing GSCM (Lorek & Spangenberg, 2014; Tumpa et al., 2019). Another problem is that consumers do not know much about green products or they focus more on price and quality (Gawusu et al., 2022; Kaur & Awasthi, 2018; Lorek & Spangenberg, 2014; Roh et al., 2022). The market's desire for green products is, therefore, uncertain. This uncertainty makes the adoption and implementation GSCMP initiatives difficult for the practitioners (Luthra et al., 2014a). Furthermore, previous research indicates that, while the lowest price is the most important consideration in low-cost nation sourcing, the suppliers' ability to implement a GSC is frequently disregarded throughout the supplier selection process. As a result, enterprises in developed nations prioritise obtaining the highest possible price for their products as their primary competitive advantage (Roh et al., 2022). In other words, it is more difficult for businesses in emerging nations to use GSCMP when there is no customer demand.

This study uses the AHP, often known as the AHP a multi-criteria decision-making method developed to deal with complex problems incorporating a number of criteria (Saaty, 1977, 1980; Saaty & Vargas, 2012). It is a useful and flexible tool for assisting decision-makers in prioritising tasks and selecting the best course of action while taking into consideration both qualitative and quantitative aspects of a scenario. The AHP breaks down the decision-making process into a hierarchical structure and employs pair-wise comparison matrices. It is a useful technique for analysing decision alternatives, selecting the best options based on the preferences of the decision-maker and rating them (Saaty & Vargas, 2012). The approach ranks the criteria in accordance with the relative importance of the factors impacting decision-making. Researchers have used the AHP technique to study supply chain characteristics, including supplier selection, green practices drivers and obstacles, and green purchasing and procurement (Chan et al., 2014; Ilyas et al., 2020). Handfield et al. (2002) recommended making environmentally responsible purchases based on AHP. Sarkis (2003) used ANP to develop a six-dimension strategic decision framework for managing a GSC. Lee et al. (2009) simulated the capabilities of green providers and the ensuing assessment and selection using Delphi and fuzzy extended AHP. In order to assess the usage of AHP, Vinodh et al. (2013) did a case study of an Indian manufacturing company and used AHP to choose the optimal lean concept. Many authors have employed different multiple criteria decision-making techniques to execute the GSCM, with the AHP 2005 being one of them (Dey & Cheffi, 2013; Haiyun et al., 2021 Hsu & Hu, 2008; Ilyas et al., 2020; Mangla et al., 2015; Mathiyazhagan et al., 2013; Sarmiento & Thomas, 2010; Wang et al., 2013).

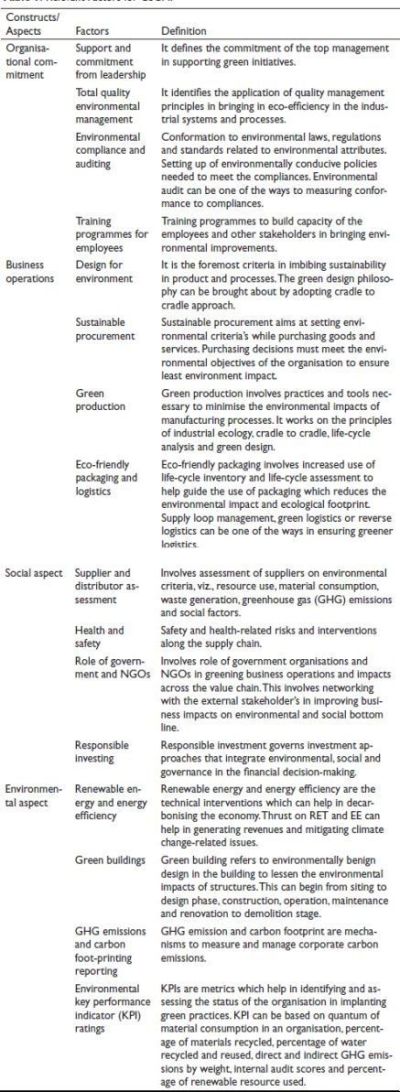

The literature highlights some innovative practices that firms have started to adopt that aids to greening of supply chain such as the implementation of an environmental management system, strategies for green procurement, adoption of green design practices, making use of environment-friendly ingredients, process optimisation, development of green product and use of innovative green practices such as environmentally responsible product packaging and labelling, and use of environmentally friendly distribution and transportation. Table 1 shows the relevant factors considered in the literature for GSCM.

Table 1. Relevant Factors for GSCM.

Methodology

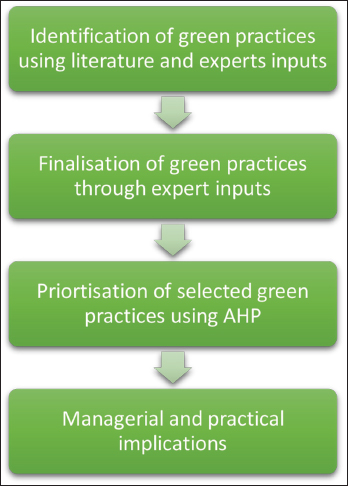

With the aim of developing a practical model, in-depth analysis of the existing literature as well as unstructured interviews with business executives, academics, consultants and sustainability experts were conducted. The process contributed to the development of a set of pertinent criteria required for evaluation taking into account the social, economic, technological and environmental concerns. The assessment criteria were created from the viewpoint of the decision-making team, and surveys were sent. As a result, more objective evaluation standards may be examined. In addition, a survey was conducted to determine the GSCM standards. As a consequence, the current study accepted and considered the criteria from a literature review as well as professional viewpoints.

The current study is divided into two stages: first, identifying the criteria to be utilised for alternative evaluation and second, performing the AHP computation, in which weights were assigned to the criteria and their relative relevance was determined. In a natural, pair-wise approach, the AHP technique makes a relative comparison of the criteria or alternatives to a criterion. It does this by employing a fundamental absolute number scale that has been demonstrated in use and supported by physical and choice problem tests. When compared to other scales used for the purpose, the basic scale captures individual preferences for both quantitative and qualitative features equally well or better. It converts each individual's choices into ratio scale weights that may be put together to generate a linear additive weight for each alternative. The outcome can be used to rank and compare possibilities, assisting the decision-maker in making a choice. Table 2 shows the list of criteria that were taken into consideration for the study based on the literature support.

Data Collection

This study conducted a comprehensive search of academic journals, databases and bibliographical sources related to the topic of GSC practices. A thorough literature search of real-world case studies on GSCM practices and their implementation was carried out to identify the key driving forces behind the decision to choose and the final implementation of green practices. A well-structured standardised questionnaire was developed and administered to the experts who rated and ranked all the criteria. The responses given by the several experts in this field were categorised according to industry. The six sectors that were chosen and categorised were consulting, banking, IT, FMCG, energy and telecom. Consulting refers to the remarks and responses given by experts who have cross-functional domain expertise across many businesses. Each aspect was studied with respect to the industry type as to which of the aspects and factors are important and critical to their respective supply chains in increasing the green quotient.

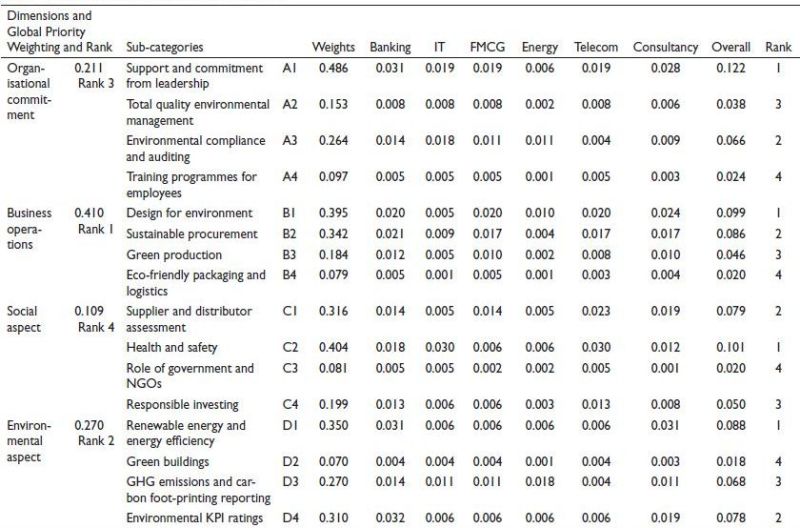

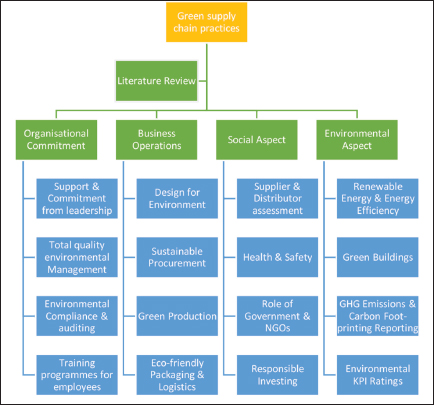

The next two phases in which the data are used are outlined. The idea (aspects) and its constituent parts are first determined through a literature study in order to arrive at the multivariable criteria for an efficient (green) supply chain. After expert examination, 16 practices in total were chosen for further evaluation to determine their relative importance utilising AHP (Tables 3–7). A survey questionnaire with four main elements defining the sustainability in the supply chain and various sub-factors was developed in order to gather data for this (Figure 1). This poll solicited responses from several business experts in the supply chain, environment, social, sustainability and climate change domains.

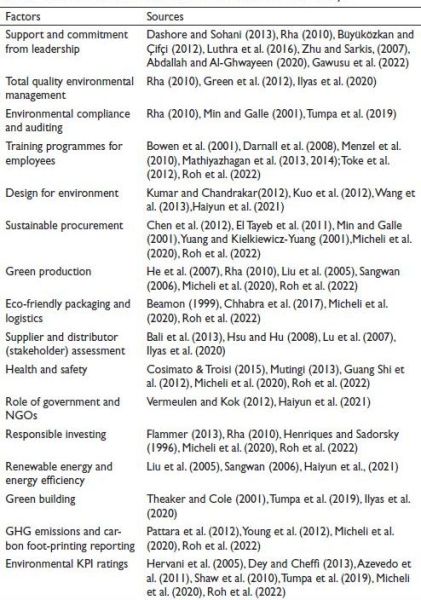

Table 2. Environmental and Social Evaluation Criteria Used in the Study.

The research framework consisting of hierarchical levels employed in the current study has been shown in Figure 2. The purpose, criteria, sub-criteria and alternatives/factors of the AHP approach are broken down into the problem's aim, according to Saaty (1980) and Dey and Cheffi (2013). The hierarchical structure (Figure 2) consists of three tiers: Level 2 evaluates the relative value of the four categories of GSC practices, Level 3 evaluates the relative value of the 16 sub-practices and Level 1 evaluates the GSC practices themselves. Weights were given to each category of green practices in pair-wise comparison matrices in order to determine the relative significance.

Table 3. Pair-wise Assessment Matrix for ‘Organisational Commitment’ Category for GSCM.

Note: A1: Support and commitment from leadership; A2: Total quality environmental management; A3: Environmental compliance and auditing, A4: Training programmes for employees.

Table 4. Pair-wise Assessment Matrix for ‘Business Operations’ Category for GSCM.

Note: B1: Design for environment; B2: Sustainable procurement; B3: Green production; B4: Eco-friendly packaging and logistics.

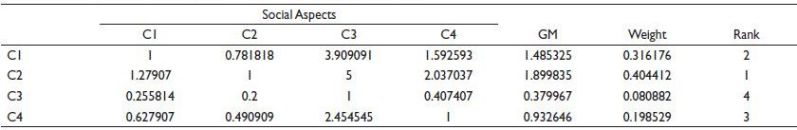

Table 5. Pair-wise Assessment Matrix for ‘Social Aspect’ Category for GSCM.

Note: C1: Supplier and distributor assessment; C2: Health and safety; C3: Role of government and NGOs; C4: Responsible investing.

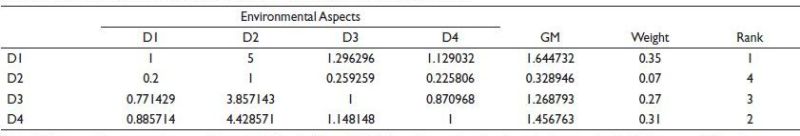

Table 6. Pair-wise Assessment Matrix for ‘Environmental Aspect’ Category for GSCM.

Note: D1: Renewable energy and energy efficiency; D2: Green buildings; D3: GHG emissions and carbon foot-printing reporting; D4: Environmental KPI ratings.

Table 7. The Overall AHP Matrix on the Construct.

Figure 1. Decision Hierarchy of Green Practices for GSCM.

The stepwise procedure employed in this study is detailed below.

Step 1: Establishing the goal

By identifying green practices (environmental and sustainability factors), the goal of making the supply chain more environmentally friendly was reviewed.

Step 2: Establishing the hierarchical framework

After establishing the hierarchical structure comprising decision components, the decision-makers were asked to assess option alternatives and criteria pair-wise using a scale.

Step 3: Developing the pair-wise comparison matrix

Next, the pair-wise comparison matrices set was developed. The elements in the level directly underneath each element in a higher level were compared to each other.

Step 4: Calculating the eigenvalues, eigenvectors and relative importance weights

Figure 2. Hierarchal Levels Representing the Factors and Sub-factorial Structure of the Construct.

Eigenvalues and eigenvectors were calculated using pair-wise comparison matrices that were analysed to determine the relative relevance of the factor weights.

Step 5: Calculation of consistency ratio

The consistency index (CI) was computed for each matrix using Equation (1), while, Equation (2) was used to determine the consistency ratio (CR) based on the CI and random consistency index (RI).

The CI and CR are defined as follows:

CI for each matrix of order n by the equation:

The CR is then computed using the following equation:

Where depending upon the order of matrix RI varies accordingly.

If the value of CR is equal to or less than that value, or if it implies a high degree of consistency in the comparison assessments represented in that matrix, the evaluation inside the matrix is judged to be acceptable. In contrast, if CR exceeds the allowed number, there has been some discrepancy in the evaluation process and has to be evaluated, reassessed and improved. When ranking a collection of criteria, a decision-maker's dependability is improved by having an adequate CR.

Result and Discussion

In order to rate the GSCM practices, the study used an analytical hierarchical framework. Organisational commitment, company operations, social aspect and environmental aspect were all assessed against one another on a pair-by-pair basis. The construct comprises 16 auxiliary factors in addition to 4 core variables. Pair-wise comparisons were performed for each category of GSC practices, and relative weights were established (Tables 3–6).

Organisational Commitment

GSCM mechanism aids in the integration of environmental issues into the supply chain management process starting from the product development stage to its final delivery.

The AHP table shows that leadership support and commitment are among the most important and beneficial factors for a firm to start greening its supply chain when comparing the four main components of this component across all industries. The internal management role play can be seen as a tactical facilitator for attaining the goals of GSCM implementation. A supply chain’s sustainability may be considerably increased while reducing risks and liabilities by setting long-term strategic goals. As stated by senior management and its leadership, GSCM adoption in any organisation should ideally come from the business philosophy of the company (Abdallah & Al-Ghwayeen, 2020; Dubey et al., 2015a, 2015b; Haiyun et al., 2021; Lorek & Spangenberg, 2014; Luthra et al., 2016; Micheli et al., 2020; Roh et al., 2022; Tumpa et al., 2019). The findings of the current study also support the same notion. The engagement of senior management, commitment to implementing environmentally friendly practices and responsibility towards environmental goals are, therefore, necessary for creating a roadmap for becoming green (Assumpção et al., 2022; Haiyun et al., 2021; Ilyas et al., 2020; Luthra et al., 2016). Top-level commitment may assure access to any necessary financial and human resource investments. Strong governance structures and strong commitment from decision-makers are crucial for a company to pick sustainability measures that directly support the business goals. Thus, in order to embrace sustainability efforts in supply chains, top management must be committed to going beyond compliance and regulation, and the government must play a role through legislation.

Environmental compliance and audits rank as the second-highest priority in the area of organisational commitment. It is evident that regulations, laws, standards and audits are evolving as part of compliances, which are the main facilitators in dictating environmental measures (Malviya & Kant, 2016; Micheli et al., 2020; Roh et al., 2022; Tumpa et al., 2019). In order to enhance environmental and economic performance, the organizations must redesign their processes and revamp their systems to become compliant in their business operations (Gawusu et al., 2022; Koh et al., 2012; Lee et al., 2009). According to Drohomeretski et al. (2014) and Mudgal et al. (2010), it may be used as a framework for analysing current practices and implementing strategies that satisfy environmental criteria. Environmental compliance and audits give better insight into the compliance status of a facility and its operations. These can be used to identify environmental liabilities related to a facility's operations, such as sloppy maintenance, careless handling, storage, disposal of hazardous materials, operational inefficiencies, faulty or misused equipment that results in spills or releases of hazardous materials, risks to human health, or improper permitting and recordkeeping that can lead to fines and the loss of a company's operating licence.

Business Operations

When comparing the four primary components of this characteristic across all industries, DfE has the greatest value. The DfE concept promotes the idea that environmental issues should be considered at every level of the manufacturing process. The functionality viewpoint includes design for recycling (RECY), manufacture (REMAN), reuse (REUSE), disassembly (DISASS), and disposal (DISP). If goods are to considerably minimise environmental damage throughout the course of their existence, environmentally friendly technologies must be adopted from the beginning of the design process onward. Planning for the environment may also be very profitable when the product is still in the operating stage. DfE tools can assist in decreasing the efforts required for environmental evaluation because of their direct integration into the designer’s workflow.

The second most significant argument in favour of greening operations was found to be sustainable procurement. Two instances of GSCM tactics include local sourcing and buying eco-friendly products. Given the concept of global supply chains, where producers and buyers are distributed around the world, local sourcing may be a positive practice that is connected to sustainability. Sustainable purchasing is given a high emphasis by businesses nowadays. It may promote competitiveness, cut down on waste, boost profitability and improve a company's reputation. By sourcing items, they might support the growth of the local economy and the creation of jobs. It also encourages cost reductions and revenue growth. According to Teixeira et al. (2016), one of the simplest methods to implement green practices is through green buying. It minimises the environmental impact while maximising economic and social value by adding pertinent sustainability factors into the procurement practice. As logistics and transportation operations contribute 5.5% of the world’s carbon emissions, focusing on these activities may have a major influence on a company's GHGs emission and carbon footprint. Therefore, from a sustainability standpoint, logistics-related operations can significantly affect the performance of the supply chain. To enhance environmental performance throughout the logistics stage of the supply chain, transportation efficiency, route optimisation and storage may be used.

Social Aspect

Health and safety has the highest value when the four parts of this element are evaluated across all sectors. Taking care of health and safety issues may be seen as a way to increase staff productivity, which is advantageous for the company. The second most crucial factor is the appraisal of suppliers and distributors. As a result, suppliers are one of the key stakeholders and significant contributors to greening supply chains (Malviya & Kant, 2016). The cooperation of suppliers at the upstream and distributors at the downstream of the supply chain is essential to achieving the anticipated environmental goals. Businesses are using a multitude of regulatory inspections and processes to ensure that suppliers follow environmental norms and criteria (Abdallah & Al-Ghwayeen, 2020; Haiyun et al., 2021; Tumpa et al., 2019). Walton et al. (1998) developed a strategy for greening the supply chain and advocated for supplier’s participation in environmental management practices. Hervani et al. (2005) developed an integrated framework for the analysis, creation and assessment of GSCM performance tools. By incorporating external stakeholders, they might be linked to proactive supply chain interventions and could be crucial to business operations that are environmentally friendly. Increased environmental performance, capacity expansion and minor operational improvements are only a few benefits of an effective supplier assessment procedure (Assumpção et al., 2022; Gawusu et al., 2022; Haiyun et al., 2021; Ilyas et al., 2020; Micheli et al., 2020; Roh et al., 2022; Zhu et al., 2013). The benefits frequently involve purchasing from suppliers who provide high standards for product and service levels together with enough capacity and commercial stability, according to Zhu et al. (2013). Noci (1997) has created the performance standards for the green supplier selection procedure. Shen et al. (2013) recommended evaluating the green suppliers using a fuzzy method. Finding and eliminating supply chain-hidden cost drivers can be aided by customer and supplier assessment. To build a variety of suppliers and enhance environmental performance, supply chain strategies can be adopted, such as those that are risk- or opportunity-oriented. A strategic approach to managing supplier relationships is a consideration at each stage of this process and is a key enabler for creating mutual value.

Environmental Aspect

When comparing the four key variables of this feature across all industries, the AHP table revealed that renewable energy and energy efficiency (0.350) had the highest value, making it the most important and important element. One method of transitioning to a low-carbon economy in an environmentally friendly approach is energy management. Energy efficiency may be seen as a low-hanging fruit, with the potential to drastically reduce energy waste and carbon emissions through optimising energy usage through better housekeeping, technological development, retrofits or technological innovation. In response to the world's rising energy requirements and concerns about climate change, the transition to renewable energy technologies is opening up new possibilities for alleviating pressure on conventional sources of energy. Investment in the technologies advocating renewable energy is another initiative that can lessen the environmental footprints that traditional energy sources leave behind on a global scale. When this is seen as a strategic asset as opposed to a tactical investment, it may result in cost savings and reduced risk throughout the supply chain.

The second most crucial factor is the environmental KPI rating (0.310). The degree to which sustainability goals and targets have been met in real practice may be determined using KPIs (Abdallah & Al-Ghwayeen, 2020; Haiyun et al., 2021). Well-defined supply chain performance indicators can help with environmental quality measurement and management. Performance indicators based on environmental elements such as GHG emissions, health and safety, resource consumption (energy, water and materials), waste reduction, stakeholder engagement, product quality and material handling can be set to measure a company's performance along the triple bottom line, in accordance with Harms et al. (2013). Many conceptual frameworks for integrating social and environmental responsibility issues into performance measurement systems have been created and employed. The establishment of KPIs on environmental and social qualities has been advocated in earlier research studies (Assumpção et al., 2022; Gawusu et al., 2022; Haiyun et al., 2021; Ilyas et al., 2020; Searcy, 2012). Further, these KPIs can be used in the performance measurement framework to benchmark the company’s sustainability endeavours.

Green supply networks are thought to benefit greatly from measures such as GHG emissions and carbon footprint. The GHGs emitted over time by various operations or businesses in the supply chain are measured by carbon footprints. This activity enables the monitoring of scope three emissions, the majority of which are produced through supply chain activities. The integration of these externalities into operations, procurement and logistics can minimise supply chain consequences by investing in relevant environmental interventions (cleaner technology, cleaner production and sustainable procurement) (Abdallah & Al-Ghwayeen, 2020; Assumpção et al., 2022; Haiyun et al., 2021; Ilyas et al., 2020; Lee et al., 2012). This necessitates a thorough approach that links supply chain decisions to the triple bottom line of profit, profit and planet (Kumar et al., 2012; Tumpa et al., 2019). Thus, it can be concluded that KPIs could be instrumental in deploying sustainability (Micheli et al., 2020; Roh et al., 2022).

The overall prioritisation comprising of the weighting and ranking of criteria and sub-criteria to implement GSCM is given in Table 7. Business operations received the highest global weighting and social aspects the lowest global weighting. They are ranked first and fourth, respectively. Environmental aspects and organisational commitment obtained second and third rank, respectively. Further, various sub-factors in each dimension were also ranked. A pair-wise matrix was created to further determine the relative significance and weights (Table 7). The leadership support and commitment factor has the highest rating in the organisational commitment component (0.486), followed by environmental compliance and auditing (0.264). Similarly to this, the aspect of business operations assigned DfE (0.395) and green practices such as sustainable procurement the highest weight. The second most significant element in the greening of the supply chain, after health and safety (0.40), was the practice of reviewing suppliers and distributors, which came in at number two (0.316). The AHP matrix indicated that the relevance of creating KPIs (0.310) and using renewable energy (0.350) for the 'Environment' element was highest.

Conclusion

The current study may be useful in understanding various elements and strategies and how they relate to a company's efforts to become green. The proposed framework may assist decision-makers to gauge how different stakeholders in an organisation see GSCM and may help managers better grasp GSCM practices. This study might aid GSCM practitioners in choosing appropriate tactics to more closely align with environmental standards and consumer demands. The organisations will be able to gain cost advantages as well as a better brand image with the proper selection of GSCM implementation tactics. The proposed model presented in the study would help the decision-makers to be better prepared, understand and address the several complexities of the GSCM problem and prioritise them for competitive advantage and efficient management. The recommended AHP-based decision model may ease decision-making as it thoroughly assesses the relative dominance of the pertinent criteria and alternatives by explicitly accounting for the various types of interdependencies existing in the decision structure.

The current study highlights several supply chain components and creates a paradigm for GSCM. The findings of the study may serve as guidelines for companies to streamline their operations by considering the social and environmental aspects. The suggested method, which is based on expert paired comparison assessment, has benefits for both physical and abstract criteria. The research may be broadened to include other industrial sectors because the various elements may possibly differ based on the type of industry. The approach might also help supply chain managers prioritise their sustainability projects for corporate goals including risk reduction, cost control and income development.

Since there could be prejudices and misunderstandings regarding the underlying issues that lead to insufficient solutions, the presented model cannot be applied to all situations. This may be considered as one of the limitations of this study. Thus, it is imperative that future research ensure that there is less misunderstanding. Depending on the social, cultural and geographic environment, the ranking for the evaluation criterion may also alter. In this area of study, it may also be beneficial to assess the model using sensitivity analysis and change as necessary by adding or eliminating particular criteria. The decision-makers will be able to make a conclusion that is more sensible, obvious, logical and systematic as a consequence.

Declaration of Conflicting of Interest

The authors have no competing interests to declare that are relevant to the content of this article.

Funding

The authors received no financial support for the research, authorship and/or publication of this article.

ORCID iD

Samridhi Kapoor  https://orcid.org/0000-0001-6132-1500

https://orcid.org/0000-0001-6132-1500

Abdallah, A. B., & Al-Ghwayeen, W. S. (2020). Green supply chain management and business performance: The mediating roles of environmental and operational performances. Business Process Management Journal, 26(2), 489–512.

Al Zaabi, S., Al Dhaheri, N.,& Diabat, A. (2013). Analysis of interaction between the barriers for the implementation of sustainable supply chain management. The International Journal of Advanced Manufacturing Technology, 68(1), 895–905.

Assumpção, J. J., Campos, L. M., Plaza-Úbeda, J. A., Sehnem, S., & Vazquez-Brust, D. A. (2022). Green supply chain management and business innovation. Journal of Cleaner Production, 367(1), 132877.

Azevedo, S. G., Carvalho, H., & Machado, V. C. (2011). The influence of green practices on supply chain performance: A case study approach. Transportation Research Part E: Logistics and Transportation Review, 47(6), 850–871.

Bali, O., Kose, E., & Gumus, S. (2013). Green supplier selection based on IFS and GRA. Grey Systems: Theory and Application, 3(2), 158–176.

Beamon, B. M. (1999). Designing the green supply chain. Logistics Information Management, 12(4), 332–342.

Bowen, F. E., Cousins, P. D., Lamming, R. C., & Farukt, A. C. (2001). The role of supply management capabilities in green supply. Production and Operations Management, 10(2), 174–189.

Büyüközkan, G., & Çifçi, G. (2012). Evaluation of the green supply chain management practices: A fuzzy ANP approach. Production Planning & Control, 23(6), 405–418.

Chan, H. K., Wang, X., & Raffoni, A. (2014). An integrated approach for green design: Life-cycle, fuzzy AHP and environmental management accounting. The British Accounting Review, 46(4), 344–360.

Chen, C. C., Shih, H. S., Shyur, H. J., & Wu, K. S. (2012). A business strategy selection of green supply chain management via an analytic network process. Computers & Mathematics with Applications, 64(8), 2544–2557.

Chhabra, D., Garg, S. K., & Singh, R. K. (2017). Analyzing alternatives for green logistics in an Indian automotive organization: A case study. Journal of Cleaner Production, 167(1), 962–969.

Chiou, T. Y., Chan, H. K., Lettice, F., & Chung, S. H. (2011). The influence of greening the suppliers and green innovation on environmental performance and competitive advantage in Taiwan. Transportation Research Part E: Logistics and Transportation Review, 47(6), 822–836.

Cosimato, S., & Troisi, O. (2015). Green supply chain management: Practices and tools for logistics competitiveness and sustainability. The DHL case study. The TQM Journal, 27(2), 256–276.

Darnall, N., Jolley, G. J., & Handfield, R. (2008). Environmental management systems and green supply chain management: Complements for sustainability? Business Strategy and the Environment, 17(1), 30–45.

Dashore, K., & Sohani, N. (2013). Green supply chain management-barriers & drivers: A review. International Journal of Engineering Research and Technology, 2(4), 2021–2030.

Dey, P. K., & Cheffi, W. (2013). Green supply chain performance measurement using the analytic hierarchy process: A comparative analysis of manufacturing organisations. Production Planning & Control, 24(8–9), 702–720.

de Oliveira, U.R., Espindola, L.S., da Silva, I.R., da Silva, I.N., & Rocha, H.M. (2018). A systematic literature review on green supply chain management: Research implications and future perspectives. Journal of Cleaner Production, 187(1), 537–561.

Drohomeretski, E., Da Costa, S.G., & De Lima, E.P. (2014). Green supply chain management: Drivers, barriers and practices within the Brazilian automotive industry. Journal of Manufacturing Technology Management, 25(8), 1105–1134.

Dubey, R., Gunasekaran, A., & Ali, S. S. (2015a). Exploring the relationship between leadership, operational practices, institutional pressures and environmental performance: A framework for green supply chain. International Journal of Production Economics, 160(1), 120–132.

Dubey, R., Gunasekaran, A., Papadopoulos, T., & Childe, S. J. (2015b). Green supply chain management enablers: Mixed methods research. Sustainable Production and Consumption, 4(1), 72–88.

El Tayeb, T.K., Zailani, S., & Ramayah, T. (2011). Green supply chain initiatives among certified companies in Malaysia and environmental sustainability: Investigating the outcomes. Resources, Conservation and Recycling, 55(5), 495–506.

Fahimnia, B., Sarkis, J., & Davarzani, H. (2015a). Green supply chain management: A review and bibliometric analysis. International Journal of Production Economics, 162(1), 101–114.

Fahimnia, B., Sarkis, J., & Eshragh, A. (2015b). A tradeoff model for green supply chain planning: A leanness-versus-greenness analysis. Omega, 54(1), 173–190.

Flammer, C. (2013). Corporate social responsibility and shareholder reaction: The environmental awareness of investors. Academy of Management Journal, 56(3), 758–781.

Gawusu, S., Zhang, X., Jamatutu, S. A., Ahmed, A., Amadu, A. A., & Djam Miensah, E. (2022). The dynamics of green supply chain management within the framework of renewable energy. International Journal of Energy Research, 46(2), 684–711.

Green, K. W., Zelbst, P. J., Meacham, J., & Bhadauria, V. S. (2012). Green supply chain management practices: Impact on performance. Supply Chain Management: An International Journal, 17(3), 290–305.

Guang Shi, V., Lenny Koh, S.C., Baldwin, J., & Cucchiella, F. (2012). Natural resource based green supply chain management. Supply Chain Management: An International Journal, 17(1), 54–67.

Haiyun, C., Zhixiong, H., Yüksel, S., & Dinçer, H. (2021). Analysis of the innovation strategies for green supply chain management in the energy industry using the QFD-based hybrid interval valued intuitionistic fuzzy decision approach. Renewable and Sustainable Energy Reviews, 143(1), 110844.

Handfield, R., Walton, S. V., Sroufe, R., & Melnyk, S. A. (2002). Applying environmental criteria to supplier assessment: A study in the application of the analytical hierarchy process. European Journal of Operational Research, 141(1), 70–87.

Harms, D., Hansen, E. G., & Schaltegger, S. (2013). Strategies in sustainable supply chain management: An empirical investigation of large German companies. Corporate Social Responsibility and Environmental Management, 20(4), 205–218.

He, Y., Liu, F., Cao, H., & Zhang, H. (2007). Process planning support system for green manufacturing and its application. Frontiers of Mechanical Engineering in China, 2, 104–109.

Henriques, I., & Sadorsky, P. (1996). The determinants of an environmentally responsive firm: An empirical approach. Journal of Environmental Economics and Management, 30(3), 381–395.

Hervani, A. A., Helms, M. M., & Sarkis, J. (2005). Performance measurement for green supply chain management. Benchmarking: An International Journal, 12(4), 330–353.

Hoejmose, S., Brammer, S., & Millington, A. (2012). ‘Green’ supply chain management: The role of trust and top management in B2B and B2C markets. Industrial Marketing Management, 41(4), 609–620.

Hsu, C. W., & Hu, A. H. (2008). Green supply chain management in the electronic industry. International Journal of Environmental Science & Technology, 5, 205–216.

Hsu, C. W., Kuo, T. C., Chen, S. H., & Hu, A. H. (2013). Using DEMATEL to develop a carbon management model of supplier selection in green supply chain management. Journal of Cleaner Production, 56, 164–172.

Ilyas, S., Hu, Z., & Wiwattanakornwong, K. (2020). Unleashing the role of top management and government support in green supply chain management and sustainable development goals. Environmental Science and Pollution Research, 27(1), 8210–8223.

Kaur, J., & Awasthi, A. (2018). A systematic literature review on barriers in green supply chain management. International Journal of Logistics Systems and Management, 30(3), 330–348.

Koh, S. C., Gunasekaran, A., & Tseng, C. S. (2012). Cross-tier ripple and indirect effects of directives WEEE and RoHS on greening a supply chain. International Journal of Production Economics, 140(1), 305–317.

Kumar, R., & Chandrakar, R. (2012). Overview of green supply chain management: Operation and environmental impact at different stages of the supply chain. International Journal of Engineering and Advanced Technology, 1(3), 1–6.

Kumar, S., Teichman, S., & Timpernagel, T. (2012). A green supply chain is a requirement for profitability. International Journal of Production Research, 50(5), 1278–1296.

Kuo, T. C., Hsu, C. W., Ku, K. C., Chen, P. S., & Lin, C. H. (2012). A collaborative model for controlling the green supply network in the motorcycle industry. Advanced Engineering Informatics, 26(4), 941–950.

Lee, A. H., Kang, H. Y., Hsu, C. F., & Hung, H. C. (2009). A green supplier selection model for high-tech industry. Expert Systems with Applications, 36(4), 7917–7927.

Lee, S. M., Kim, S. T., & Choi, D. (2012). Green supply chain management and organizational performance. Industrial Management & Data Systems, 112(8), 1148–1180.

Lee, S. Y. (2008). Drivers for the participation of small and medium-sized suppliers in green supply chain initiatives. Supply Chain Management: An International Journal, 13(3), 185–198.

Liu, F., Yin, J. X., Cao, H. J., & He, Y. (2005). Investigations and practices on green manufacturing in machining systems. Journal of Central South University of Technology, 12(2), 18–24.

Lorek, S., & Spangenberg, J. H. (2014). Sustainable consumption within a sustainable economy: Beyond green growth and green economies. Journal of Cleaner Production, 63(1), 33–44.

Lu, L. Y., Wu, C. H., & Kuo, T. C. (2007). Environmental principles applicable to green supplier evaluation by using multi-objective decision analysis. International Journal of Production Research, 45(18–19), 4317–4331.

Luthra, S., Garg, D., & Haleem, A. (2014a). Green supply chain management: Implementation and performance: A literature review and some issues. Journal of Advances in Management Research, 11(1), 20–46.

Luthra, S., Garg, D., & Haleem, A. (2016). The impacts of critical success factors for implementing green supply chain management towards sustainability: An empirical investigation of Indian automobile industry. Journal of Cleaner Production, 121, 142–158.

Luthra, S., Qadri, M. A., Garg, D., & Haleem, A. (2014b). Identification of critical success factors to achieve high green supply chain management performances in Indian automobile industry. International Journal of Logistics Systems and Management 1, 18(2), 170–199.

Malviya, R. K., & Kant, R. (2016). Hybrid decision making approach to predict and measure the success possibility of green supply chain management implementation. Journal of Cleaner Production, 135, 387–409.

Mangla, S. K., Kumar, P., & Barua, M. K. (2015). Risk analysis in green supply chain using fuzzy AHP approach: A case study. Resources, Conservation and Recycling, 104(1), 375–390.

Mathiyazhagan, K., Govindan, K., & Noorul Haq, A. (2014). Pressure analysis for green supply chain management implementation in Indian industries using analytic hierarchy process. International Journal of Production Research, 52(1), 188–202.

Mathiyazhagan, K., Govindan, K., NoorulHaq, A., & Geng, Y. (2013). An ISM approach for the barrier analysis in implementing green supply chain management. Journal of Cleaner Production, 47(1), 283–297.

Meera, B. L., & Chitramani, P. (2014). Environmental Sustainability through green supply chain management practices among Indian manufacturing firms with special reference to Tamilnadu. International Journal of Scientific and Research Publications, 4(3), 1–8.

Menzel, V., Smagin, J., & David, F. (2010). Can companies profit from greener manufacturing? Measuring Business Excellence, 14(2), 22–31.

Micheli, G. J., Cagno, E., Mustillo, G., & Trianni, A. (2020). Green supply chain management drivers, practices and performance: A comprehensive study on the moderators. Journal of Cleaner Production, 259(1), 121024.

Min, H., & Galle, W. P. (2001). Green purchasing practices of US firms. International Journal of Operations & Production Management, 21(9), 1222–1238.

Mudgal, R. K., Shankar, R., Talib, P., & Raj, T. (2010). Modelling the barriers of green supply chain practices: An Indian perspective. International Journal of Logistics Systems and Management, 7(1), 81–107.

Murphy, P. R., & Poist, R. F. (2003). Green perspectives and practices: A ‘comparative logistics’ study. Supply Chain Management: An International Journal, 8(2), 122–131.

Mutingi, M. (2013). Developing green supply chain management strategies: A taxonomic approach. Journal of Industrial Engineering and Management (JIEM), 6(2), 525–546.

Noci, G. (1997). Designing ‘green’ vendor rating systems for the assessment of a supplier's environmental performance. European Journal of Purchasing & Supply Management, 3(2), 103–114.

Pattara, C., Raggi, A., & Cichelli, A. (2012). Life cycle assessment and carbon footprint in the wine supply chain. Environmental Management, 49, 1247–1258.

Rha, J. S. (2010). The impact of green supply chain practices on supply chain performance. Dissertations and Theses from the College of Business Administration, University of Nebraska– Lincoln, USA.

Roh, T., Noh, J., Oh, Y., & Park, K. S. (2022). Structural relationships of a firm's green strategies for environmental performance: The roles of green supply chain management and green marketing innovation. Journal of Cleaner Production, 356(1), 131877.

Saaty, T. L. (1977). A scaling method for priorities in hierarchical structures. Journal of Mathematical Psychology, 15(3), 234–281.

Saaty T., L. (1980). The analytic hierarchy process. McGraw-Hill International.

Saaty, T. L., & Vargas, L. G. (2012). Models, methods, concepts & applications of the analytic hierarchy process (Vol. 175). Springer Science & Business Media.

Sangwan, K. S. (2006). Performance value analysis for justification of green manufacturing systems. Journal of Advanced Manufacturing Systems, 5(01), 59–73.

Sarkis, J. (2003). A strategic decision framework for green supply chain management. Journal of Cleaner Production, 11(4), 397–409.

Sarkis, J., Zhu, Q., & Lai, K. H. (2011). An organizational theoretic review of green supply chain management literature. International Journal of Production Economics, 130(1), 1–15.

Sarmiento, R., & Thomas, A. (2010). Identifying improvement areas when implementing green initiatives using a multitier AHP approach. Benchmarking: An International Journal, 17(3), 452–463.

Searcy, C. (2012). Corporate sustainability performance measurement systems: A review and research agenda. Journal of Business Ethics, 107(1), 239–253.

Seuring, S., & Müller, M. (2008). From a literature review to a conceptual framework for sustainable supply chain management. Journal of Cleaner Production, 16(15), 1699–1710.

Sharfman, M. P., Shaft, T. M., & Anex Jr, R.P. (2009). The road to cooperative supply-chain environmental management: Trust and uncertainty among pro-active firms. Business Strategy and the Environment, 18(1), 1–13.

Shaw, S., Grant, D. B., & Mangan, J. (2010). Developing environmental supply chain performance measures. Benchmarking: An International Journal, 17(3), 320–339.

Shen, L., Olfat, L., Govindan, K., Khodaverdi, R., & Diabat, A. (2013). A fuzzy multi criteria approach for evaluating green supplier's performance in green supply chain with linguistic preferences. Resources, Conservation and Recycling, 74(1), 170–179.

Srivastava, S. K. (2007). Green supply-chain management: A state-of-the-art literature review. International Journal of Management Reviews, 9(1), 53–80.

Teixeira, A. A., Jabbour, C. J. C., de Sousa Jabbour, A. B.L., Latan, H., & De Oliveira, J. H.C. (2016). Green training and green supply chain management: Evidence from Brazilian firms. Journal of Cleaner Production, 116(1), 170–176.

Theaker, I. G., & Cole, R. J. (2001). The role of local governments in fostering ‘green’ buildings: A case study. Building Research & Information, 29(5), 394–408.

Thun, J. H., & Müller, A. (2010). An empirical analysis of green supply chain management in the German automotive industry. Business Strategy and the Environment, 19(2), 119–132.

Toke, L. K., Gupta, R. C., & Dandekar, M. (2012). An empirical study of green supply chain management in Indian perspective. International Journal of Applied Sciences and Engineering Research, 1(2), 372–383.

Tumpa, T. J., Ali, S. M., Rahman, M. H., Paul, S. K., Chowdhury, P., & Khan, S. A. R. (2019). Barriers to green supply chain management: An emerging economy context. Journal of Cleaner Production, 236(1), 117617.

Vermeulen, W. J. V., & Kok, M. T. J. (2012). Government interventions in sustainable supply chain governance: Experience in Dutch front-running cases. Ecological Economics, 83(1), 183–196.

Vinodh, S., Kamala, V., & Shama, M. S. (2013). Compromise ranking approach for sustainable concept selection in an Indian modular switches manufacturing organization. The International Journal of Advanced Manufacturing Technology, 64(1), 1709–1714.

Walton, S. V., Handfield, R. B., & Melnyk, S. A. (1998). The green supply chain: Integrating suppliers into environmental management processes. International Journal of Purchasing and Materials Management, 34(1), 2–11.

Wang, Y. F., Chen, S. P., Lee, Y. C., & Tsai, C. T. S. (2013). Developing green management standards for restaurants: An application of green supply chain management. International Journal of Hospitality Management, 34(1), 263–273.

Wu, G. C., Ding, J. H., & Chen, P. S. (2012). The effects of GSCM drivers and institutional pressures on GSCM practices in Taiwan’s textile and apparel industry. International Journal of Production Economics, 135(2), 618–636.

Young, D. M., Hawkins, T., Ingwersen, W., Lee, S. J., Ruiz-Mercado, G., Sengupta, D., & Smith, R. L. (2012). Designing sustainable supply chains. Chemical Engineering, 29(1), 253–258.

Yuang, A., & Kielkiewicz-Yuang, A. (2001). Sustainable supply network management. Corporate Social Responsibility and Environmental Management, 8(3), 260–268.

Zhu, Q., Dou, Y., & Sarkis, J. (2010). A portfolio-based analysis for green supplier management using the analytical network process. Supply Chain Management: An International Journal, 15(4), 306–319.

Zhu, Q., & Sarkis, J. (2004). Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. Journal of Operations Management, 22(3), 265–289.

Zhu, Q., & Sarkis, J. (2007). The moderating effects of institutional pressures on emergent green supply chain practices and performance. International Journal of Production Research, 45(18–19), 4333–4355.

Zhu, Q., Sarkis, J., & Lai, K. H. (2007). Green supply chain management: Pressures, practices and performance within the Chinese automobile industry. Journal of Cleaner Production, 15(11–12), 1041–1052.

Zhu, Q., Sarkis, J., & Lai, K. H. (2013). Institutional-based antecedents and performance outcomes of internal and external green supply chain management practices. Journal of Purchasing and Supply Management, 19(2), 106–117.