1Thakur Global Business School, Mumbai, Maharashtra, India

2Fashion Technology, Amity University, Raipur, Chhattisgarh, India

3Rajeev Gandhi College of Management Studies, Navi Mumbai, Maharashtra, India

Creative Commons Non Commercial CC BY-NC: This article is distributed under the terms of the Creative Commons Attribution-NonCommercial 4.0 License (http://www.creativecommons.org/licenses/by-nc/4.0/) which permits non-Commercial use, reproduction and distribution of the work without further permission provided the original work is attributed.

Environmental concerns are top priorities for all nations in the globe today. Organisations must thus address these problems given the ongoing pressure on them to take action that is environmentally friendly. One industry that has a negative impact on the environment is logistics. Logistics activities have greatly risen as a result of globalisation. The logistics market will reach USD 6,300 billion on a global scale by 2024, with a compound annual growth rate of 4.9% from 2019 to 2024. In order to improve the environment and reduce carbon emissions, manufacturing companies are implementing new strategies and green regulations. Green logistics has recently gained popularity in wealthy nations. Despite being in developing nations, it is still in its early stages and requires more attention. The lack of promotion and adoption of green techniques in logistics by developing nations had been questioned. For the Indian manufacturing sector, the current study focuses on green logistics drivers, challenges, practices and performance metrics (especially in the oil and gas sector). Because it is a well-known industry that generates a significant amount of carbon emissions, the oil and gas sector was chosen for the research study. This industry’s downward vertical includes the main logistics functions, such as marketing and wholesaling and has never been centred on green logistics. The implementation of the green logistics practices is governed by a number of drivers and barriers that both enable its implementation and may serve as obstacles. These factors must be thoroughly explored because they are the most important ones. This study’s main goal is to provide a conceptual framework for green logistics that will apply to the logistics activities carried out by the Indian manufacturing industry (oil and gas) and the impact they have on economic and environmental performance. In the context of the oil and gas industry, the key green logistics drivers that could facilitate the adoption of green logistics practises have been thoroughly researched. By outlining the finest green logistics methods and factors that the sector should take into account, this study is further developed. The officials and managers who work for the downward logistics of the oil and gas industry were selected for the study and the survey questionnaire was employed as the research tool. Finally, using structural equation modelling, the effects of these green logistics practises on economic and environmental performance have also been researched and examined (SEM). When developing various rules and incentives for the Indian manufacturing sector to encourage the adoption of green logistics practices, this report would be crucial for the government. The results of this study about various green logistics activities may be related to creating a long-term plan for the industrial sector. The research will be helpful to future researchers, practising managers, governmental organisations, academic institutions and the Indian manufacturing industry as a whole.

Green procurement, green logistics, logistics and distribution, occupational safety, health hazard, green marketing

Introduction

According to a report by the IBEF Knowledge Centre, India’s logistics industry is likewise growing quickly. One of India’s well-known domestic rating agencies stated that the country’s logistics market is presently valued at about USD 160 billion and is expected to increase at a rate of up to 10% in the coming years. The rise is an improvement over the compound annual growth rate (CAGR) of 7.8% that the industry had experienced over the previous five years (IBEF, n.d.).

Typically, the logistics system is blamed for having a considerable impact on global energy consumption and greenhouse gas (GHG) emissions (Kim & Han, 2011; Murphy & Poist, 2003). In the United States, the transportation sector is primarily responsible for 28% of all GHG emissions (USEPA, 2021). Stakeholders are putting more pressure on businesses to accept responsibility for the negative and damaging effects their three logistical operations have on the environment. The current study focuses on green logistics practices, which the Indian manufacturing industry is either doing now or plans to apply in its logistics operations (especially in the oil and gas industry). The implementation of the green logistics practices is governed by a number of drivers and barriers that both enable its implementation and may serve as obstacles. These ‘drivers’ and ‘barriers’ are the important elements, thus they must be thoroughly investigated. The performance will also be impacted by the use of green logistics practices. The research discusses performance in terms of both the economy and the environment.

The primary goal of this research study is to create a conceptual framework for the green logistics practises used in the operations of a specific Indian manufacturing sector (oil and gas) and their impact on the performance of the economy and the environment. By leveraging this study and investigating the green logistics techniques being used by a small portion of the Indian manufacturing sector, a theoretical framework has been developed. First, there has been a lot of research done on the key factors and obstacles that could help or impede the adoption of green logistics practises. This study is expanded upon by a list of the top green logistics strategies that the Indian manufacturing sector should take into account (especially the oil and gas industry). Their economic and environmental performances have eventually been examined in relation to green logistics techniques. Such thorough research studies could aid the Indian manufacturing sector in strategic decision-making regarding the adoption of green logistics practises for achieving environmental goals, as well as providing insight into the effects of these practises on the environmental and economic performances, thereby achieving long-term sustainability.

The move towards greening logistics, which should not only focus on following government regulations but also satisfy customer demands and uphold environmental obligations, is motivated by the rising environmental awareness. Green logistics affects society, the economy and the environment in addition to the environment. Green logistics, according to Lee and Klassen (2008), are logistics activities carried out by a business or organisation that considers environmental concerns and integrates them into the supply chain to improve environmental performance. The term ‘green logistics’ is used to describe a number of procedures that minimise the environmental issues associated with logistics operations by maintaining a balance between economic and environmental outcomes. Green logistics is the development of current logistics that emphasises the performance of these logistics-related activities in an eco-friendly manner to understand economic growth while preserving the available and existing resources, thereby safeguarding the environment from the negative effects of the activities (Zang et al., 2020).

According to a study by EyeforTransport (O’Reilly, 2007), about 25% of tested businesses in the United States, United Kingdom, Gulf countries and Asia Pacific have worked with outside logistics providers to promote their image as being more environmentally friendly or advance their green and sustainable projects. Utilising green logistics helps to promote stable growth in the economy and environment by reducing the negative effects of logistical activities on the environment, such as gas emissions, trash and noise (Wang et al., 2018). In other words, green logistics strives to reduce environmental harm and damage caused by logistics during various logistics activities and aids in environmental clean-up, allowing for the efficient and effective use of logistics resources. As a result, environmentally friendly and sustainable development is made possible. Green logistics operations consider how different distribution techniques would affect the environment, how much energy will be used during those activities, how much garbage will be produced, and how to manage that waste’s treatment (Sbihi & Eglese, 2009). According to Martinsen and Bjorklund (2012), there is an increase in demand for green logistics activities. The interest in green logistics is rising as a result of this trend. By incorporating the green concept into their logistical systems, businesses in the manufacturing industry and other sectors are forced to increase both their efficiency and environmental performance. Academics, teachers and managers are debating the environmental challenges in logistics-related operations as a result. By supporting the industrial sector’s pro-environmental initiatives, numerous reports and projections have been issued to demonstrate the significance and urgency of this area of knowledge. However, the emergence of environmental concerns in logistics operations, particularly in poor nations, is still in its infancy.

Manufacturing is the backbone of any nation and is crucial to contemporary civilisation since it encompasses a wide range of activities, from textile manufacture to steel production. Manufacturing is built on the idea of transforming raw materials into the practical goods that society needs and uses. Several divisions of the manufacturing industry exist depending on various variables. The manufacturing sector is segmented as follows according to the raw materials employed:

The oil and gas sector plays a significant role in the global logistics system, which also includes international shipping, export and import services, and inventory management. As a result, this sector provides room for a workable strategy to achieve the viability of environmentally friendly logistical activities. This is one of the justifications for taking into account this sector for implementation studies of green logistics methods in the context of Indian manufacturing. One of the most significant major non-renewable resources in the planet, petroleum is acquired from offshore or underground areas (Hussain et al., 2013). Oil is crucial because it generates income for the nation.

Given that countries with oil deposits are among the richest in the world, the worldwide supply and distribution of these reserves, as well as their consumption and production, are incredibly uneven (Yergin, 2011). By 2050, it has been predicted that there will be about 9.8 billion people on the planet (UNPD, 2017). Additionally, the population of India is growing quickly and has already surpassed 140 Crore.

India’s enormous population growth has significantly strained the country’s existing and readily accessible non-renewable resources, which in turn affects climate change. Additionally, the downward-vertical logistical activities of the oil and gas business in India make it one of the most polluting industries in the world (Abubakar, 2014). Thus, it is essential to incorporate green practices into the logistics for oil and gas, as this will aid in resolving environmental issues. In order to address some of the environmental challenges in the business, sustainable logistics methods should be implemented in the logistical operations of India’s oil and gas sector. There is a dearth of research on green logistics in this sector, and little is known about the factors that influence whether green logistics methods are adopted or used, as well as how they affect both environmental and economic performances. Only a few studies have addressed the importance of sustainability, environmental protection and GHG emission reduction measures. Although it is uncommon for research to be focused on examining the elements that affect enterprise performance (Frynas, 2009; García-Rodríguez et al., 2013; Wan Ahmad et al., 2016).

The idea of ‘green logistics’ is still in its infancy in India and requires a lot of attention. Although it is aware of the green logistics idea, the manufacturing sector is still not fully applying it. There are not many research works on the subject specifically related to the Indian manufacturing industry. Both of the green logistics strategies have been the subject of all studies. In the context of the Indian oil and gas industry, there are no studies that examine all the activities of green logistics techniques and their effects on performances. However, due to the narrow scope of this study, the researcher was unable to locate a single empirical study that addresses many green logistical challenges in one location, let alone in the context of the descending logistics activities of the Indian oil and gas business. Additionally, the majority of studies have only taken into account one or a maximum of two green logistics operations. Studies have talked about how transportation affects productivity. However, these studies do not pay attention to other performances, including economic and environmental ones. By doing the research that provides a foundation for the complete performance of green logistics practices, many holes will be filled. Research on the practices and performance difficulties of green logistics methods within the Indian manufacturing industry is lacking, according to green logistics academics. By creating a green logistics performance-based framework with the aid of various descriptive and inferential statistical studies on a subset of the Indian manufacturing industry, the current research study intended to close these gaps (oil and gas). This will make it easier for businesses in related industries to adopt green practices that will improve how they manage their overall performances.

The lockdown, slower pace of mobility and lower usage of fossil fuels have undoubtedly helped nature recover, but they are definitely not a fix. The quantity of CO2 and other GHG emissions has significantly decreased globally, and wildlife is now regaining former habitats. Different carbon policies have been developed and implemented over the last couple of decades by regulatory agencies and governments, but each of the plans has significant drawbacks.

A discussion of current carbon policies is as follows.

The United States of America saw an initial uptick in environmental-related activities and initiatives in the 1950s and 1960s (Ghosh et al., 2020). Later, the governments of numerous nations established varied carbon policies (Ghosh et al., 2017). All of these measures fall into one of three main categories: carbon taxes and prices, carbon cap-and-trade programmes and strict carbon cap policies (Ghosh et al., 2016). These policies’ mechanisms are as follows.

Literature Review

Green Logistics

The goal of logistics operations is to satisfy customers while incurring the fewest expenses and highest revenues possible. The phrase was first used in numerous reports of manufacturing companies. However, the term ‘logistics’ is now combined with ‘green’, leading to the creation of a new term ‘green logistics’.

It is also clear that the supply chain’s incorporation of environmental concerns can affect choices made about location, fuel type, raw material sourcing and route planning. According to Lee and Klassen (2008), ‘green logistics’ refers to an organisation’s activity that integrates environmental considerations into supply chain management (SCM). Green logistics practises include evaluating the environmental impact of various distribution strategies and cutting back on energy use (Sbihi & Eglese, 2009).

According to estimates, freight from logistics activities is the source of 8% of the global energy-associated carbon emissions (Karaman et al., 2020). The use and acceptance of green and low carbon logistics modes are in extensive development around the world due to the global increase in global warming and environmental degradation.

A survey of the literature has been conducted in order to explore the topics already investigated by researchers in the field of green supply chain management (GSCM) and to determine the factors for the study of GSCM.

Historical Perspective of GSCM

Since the beginning of the industrial revolution, managing industrial pollution has been a significant social problem. The Indian oil and gas industry is experiencing severe environmental challenges, as can be observed from the literature review relating export and the environment. However, the researcher is adamant that environmental concerns should not prevent a promising industry from expanding. As a result, the implementation of GSCM is required to support the expansion of the oil and gas industry and exports. To further evaluate the GSCM performance of the respondent organisations in question, it is crucial at this point to research the GSCM-related literature in order to have a thorough understanding of the premise and parameters of the GSCM.

According to Sarkis et al. (2011), the multidisciplinary field of GSCM has gained importance from academia and industry in recent years. Both environmental management and SCM literature are the sources of GSCM. Addressing the impact and connections between SCM and the environment is part of adding the ‘green’ component to supply-chain management. Since the industrial revolution, there have been significant historical concerns about industrial pollution and its impact on the environment. Adam Smith’s labour-specialisation policies spawned the growth of suppliers and vendors, manufacturing, logistics, distribution and marketing, which resulted in the creation of the specialised field of study known as SCM.

These were some of the early advancements in the field of GSCM, according to Seuring and Müller (2008), which were subjective and conceptual in nature and introduced numerous concepts and practises linked to GSCM. As the subject has expanded, case studies investigation led to the development of a theory, which was then tested through empirical studies presented as models. Therefore, GSCM refers to the process of incorporating environmental considerations into SCM, which includes product design, material sourcing and selection, manufacturing procedures, delivery of the finished product to consumers and end-of-life management of the product after its useful life (Srivastava, 2007).

Green Process Design

A straightforward method for achieving green design, according to Graedel (2002), is to remove a potentially hazardous material from a process or product or to process one that is less problematic. However, this method is occasionally unwelcome and may hasten the depletion of potentially limited resources.

Hendrickson et al. (2001) claim that because environmental issues were completely disregarded throughout the creation of new products and processes, green design aids in the development of environmentally friendly products and processes. Untreated hazardous garbage is disposed of wherever it is most convenient. By introducing the idea of green into the design process, these issues can be solved. He argued that the three objectives for a sustainable future should be the primary focus of the notion of green design:

Green Procurement

According to Salam (2008), a green purchase is one that incorporates actions such as material reduction, reuse and recycling into the purchasing process. He added that it is a solution for businesses that are both environmentally conscious and prudent financially. This idea reduces environmental effect through product selection.

Jumadi and Zailani (2010) backed up Salam’s claim by stating that ‘green procurement’ is the practice of acquiring goods or services that have a lower overall environmental impact. They recommended a few typical components of green procurement programs:

Green Manufacturing

The crucial facets of green operations include green manufacturing and remanufacturing (Srivastava, 2007). According to Johansson and Winroth (2009), green manufacturing seeks to continuously improve industrial practises and end products in order to lessen or prevent contamination of the air, water and land. Additionally, they said that by making these enhancements, hazards to humans and other species might be reduced.

Employee involvement is crucial for creating or implementing environmental performance within the company, according to Johansson and Winroth (2009). Because industries’ environmental effects have lasted for a long time, green manufacturing depends on long-term thinking. A fast shift will require greater capital investment, but if a longer time frame is taken into account, it is responsible.

Green Marketing

According to Ishaswini and Datta (2011), the creation of the green marketing mix ‘which preserves natural resources and at the same time delivers value-added products and services’ is a result of consumer consumption of eco-friendly products and attitudes toward these items.

Chen and Chai (2010) defined ‘green marketing’ as the actions made by businesses to address environmental or ‘green’ issues by providing sound products or services to satisfy consumers and society. Kumar (2011) asserts that green marketing has grown because, despite the fact that human demands are limitless, natural and manmade resources are scarce.

According to Chitra (2007), eco-friendly items are made with less harm to the environment in mind when they are planned and manufactured. When there was a great deal of discussion about Rachel Carson’s Silent Spring, which published and addressed serious concerns on the sustainable and healthy environment, in the 1960s, environmental issues gained international attention (Marly et al., 2011).

Green Logistics and Distribution

According to Jiange (2008), the growth of solid waste has a significant impact on sustainable development. To address this issue, the green packaging method is used, which covers the entirety of the package life cycle.

Indicators for system evaluation are used to monitor and manage the packaging system (Zhang & Liu, 2009). Green distribution can be broken down into green packaging and green logistics, according to Shalishali et al. (2009). Size, shape and material considerations that affect distribution also have an impact on a product’s transport characteristics. Better packaging and altered loading patterns can be employed to enhance space and decrease the amount of handling needed to offset these effects.

The oil and gas industry is one of the eight key industries and has a significant influence in the economy’s decision-making. The country’s economic expansion is closely tied to the demand for energy; as a result, it is anticipated that the oil and gas sector would expand even more, which is good news for investors. Numerous additional industrial fields are supported by this business. However, it poses a serious threat to the ecosystem and has a negative impact on many aspects of our world, including the air, water and soil.

The distributor and the oil and gas manufacturing sector are connected by a crucial logistical chain. Road transportation is used for the majority of logistics operations. This method is popular because it is adaptable and allows for the delivery of supplies to remote sections of the nation (Mariano, 2017). Oil consumption in India increased from 2008 to 2016 at a CAGR of 3.3%, reaching 4.0% in 2016. By 2025, India would surpass the United States and China as the third- and second-largest oil consumers in the world, respectively. In India, there are around 56,190 retail gas stations as of March 2016—13,000 each from Bharat Petroleum and Hindustan Petroleum Ltd, and about 25,000 from Indian Oil Corporation Ltd (Arockiaraj, 2017). Logistics activities play a significant role in the oil and gas supply chain. Discussing and analysing several important sectoral concerns may be necessary to make these logistics operations more environment friendly.

We can understand through various research papers, as described in the tabular form below.

GSCM: Research Gaps

The following gaps have been found from the review.

Objective of the Study

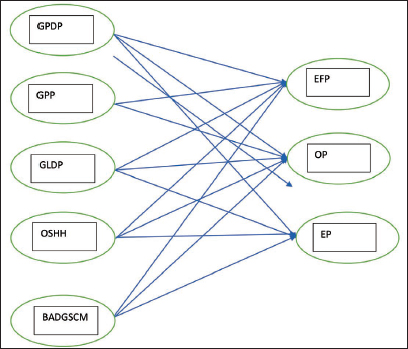

Hypotheses

Green process design practices (GPDP)

H1: GPDP has no significant impact on EFP

H2: GPDP has no significant impact on OP

H3: GPDP has no significant impact on EP

Green procurement practices (GPP)

H4: GPP has no significant impact on EFP

H5: GPP has no significant impact on OP

H6: GPP has no significant impact on EP

Green logistic and distribution practices (GLDP)

H7: GLDP has no significant impact on EFP

H8: GLDP has no significant impact on OP

H9: GLDP has no significant impact on EP

Occupation safety and health hazard (OSHH)

H10: OSHH has no significant impact on EFP

H11: OSHH has no significant impact on OP

H12: OSHH has no significant impact on EP

Barriers and drivers of green supply chain management (BADGSCM)

H13: BADGSCM has no significant impact on EFP

H14: BADGSCM has no significant impact on OP

H15: BADGSCM has no significant impact on EP

Economic financial performance (EFP)

Operational performance (OP)

Environmental Performance (EP)

Research Methodology

Defining variables:

A. Demographic variable (moderating variable)

B. Green process design practices (independent variables)

C. Green procurement practices (independent variable)

D. Green logistic and distribution practices (independent variable)

E. Occupational safety and health hazards (independent variable)

F. Barriers and drivers of GSCM (independent variable)

G. Economic and financial performance (dependent variable)

H. Operational performance (dependent variable)

I. Environmental performance (dependent variable)

Green process design practices were measured using five items. The sample items are as follows: (a) Process is designed for optimum energy consumption of material/energy. (b) Process design includes reuse, recycle and recovery of material. (c) Process design avoids or reduces use of hazardous substances. (d) Process design reduces wastage (solid, liquid and gas). (e) Process design meets environmental and safety standards. All items are measured on the 5-pointer scale as not considering, planning to consider, considering it currently, initiating the implementation and implementing successfully. Green procurement practices, green logistics and distribution practices and occupational safety and health hazard were measured using five items. All items are measured on the 5-pointer scale as not considering, planning to consider, considering it currently, initiating the implementation and implementing successfully. Barriers and drivers of GSCM were measured using five items. All items are measured on the 5-pointer scale as strongly disagree, disagree, neutral, agree and strongly agree. Economic and financial performance, operational performance and environmental performance was measured using five items. All items are measured on the 5-pointer scale as not at all, a little bit, to some degree, relatively significant and significant.

Sample: 176 responses were collected through Google Form. Error checking and verification were done for various stages of data analyses, that is, editing, coding, data entry and data analysis. Value, label, field, string, scaling for various questionnaire options were done on Smart PLS 4.

The demographic variable had 35% small-scale industries, 33.3% medium-scale industries and 31.7% large-scale industries. Type of ownership of the organisation was 36.7% private and proprietorship and 26.7% in partnership.

The methodology is the general research strategy that outlines how research is to be undertaken and, among other things, identifies the methods to be used in it. Data from 176 respondent were considered all over the country. GPDP, GPP, GLDP, OSHH and BADGSCM directly or indirectly explain EFP, OP and EP through structural equation modelling with Smart PLS 4.

Theoretical Result Framework

The conceptual framework that has been suggested demonstrates the impact of green logistics practises on economic financial, operational, and environmental performance. The effects of green logistics practises on environmental performance, operational performance, and economic financial performance are demonstrated by hypothesis H1 through H15. The major function of the research design is to establish a framework for the planned study’s use of exploratory, descriptive, and inferential analyses to test the aforementioned hypotheses and ultimately achieve the study’s objectives.

Result and Analysis

A statistical hypothesis is a claim that may be verified using data from observations that have been modelled after actual values drawn from a set of random variables. Modelled as the realised values of a set of random variables with a common probability distribution in a set of potential joint distributions, the data collection (or multiple data collections collected together) is a set of data. The set of potential probability distributions is precisely the hypothesis being tested. A statistical hypothesis test is a technique for drawing conclusions from data. A multivariate statistical analysis method used to assess structural links is called structural equation modelling.

To assess the link between observable variables and latent constructs, it combines multiple regression analysis and factor analysis.

Measure

Underlying Factors Retained Through SEM

Using structural equation modelling, hypotheses 1 through 15 were tested. The testing procedure has examined the suggested research structural models. Smart PLS 4.0 was used to calculate the simulations using structural equation modelling. Table 1 displays the fundamental factors that SEM retained. Table 2 shows the path coefficient, which is the predicted impact of an independent variable on a dependent variable after accounting for all other factors in the model. Each observed variable’s ability to accurately reflect the construct it is meant to measure is displayed in the outer loading matrix. In Table 3, it is also known as the factor loading matrix or the measurement model matrix. The coefficient of determination, or R-square, is a metric for how well a model fits the data and accounts for the variation of its endogenous variables (Table 4).

A frequently used metric to evaluate the discriminant validity of the latent variables in SEM is the heterotrait–monotrait ratio. The heterotrait measurement threshold (HTMT) is the ratio of the average correlation between items measuring different constructs to the average correlation between identical constructs. Better discriminant validity is shown by a lower HTMT score, which suggests that the constructs are distinct from one another (Table 5).

Root Mean Square Standardised Residual (SRMR): This calculates the typical discrepancy between the model’s projected values and its observed values. A better match is indicated by lower SRMR values (Table 6).

Table 1. Underlying Factors Retained Through SEM.

Source: Authors (Smart PLS 4).

Table 2. Path Coefficient.

Source: Authors (through Smart PLS 4).

Table 3. Outer Loading Matrix.

Source: Authors (through Smart PLS 4).

Table 4. R2 Overview.

Source: Authors (through Smart PLS 4).

Table 5. Discriminant Validity—Heterotrait–Monotrait Ratio.

Source: Authors (through Smart PLS 4).

Table 6. Model Fit.

Source: Authors (through Smart PLS 4).

Table 7. Path Coefficient Mean, SD, T-values and P Values.

Source: Authors (through Smart PLS 4).

Measurement Model

Quality of the construct in the study is assessed based on the evaluation of measurement model. The assessment of quality criteria starts with evaluation of factor loading which is followed by establishing the construct reliability and construct validity (Table 7).

Table 8. Construct Reliability and Validity.

Source: Authors (through Smart PLS 4).

Table 9. Fornell Larcker Criterion.

Source: Authors (through Smart PLS 4).

Factor Loading

Factor loading refers to ‘the extent to which each of the item in correlation matrix correlates with given principal component’. Factor loading can range from –1 to +1 with higher absolute value indicating a higher correlation of the item with the underlying factor. Item had factor loading in the study less than the recommended value of 0.50. Hence, items were removed for further study.

Reliability Analysis

Reliability is defined as the extent to which a measuring instrument is stable and consistent. The essence of reliability is repeatability. If an instrument is administered over and over again it will give the same result. Indicators of reliability have reliability statistic over required threshold of over 0.70 (Table 8).

Convergent Validity

Convergent validity is the degree to which multiple attempts to measure the same concept are in agreement. The idea is that two or more measures of the same thing should co-vary highly if they are the valid measure of concept. When average variance extracted (AVE) value is greater than or equal to the recommended value of 0.50, item converge to measure the underlying construct and hence convergent validity is established (Fornell & Larcker, 1981) (Table 9).

Conclusion

The industries will be assisted in removing the main obstacles to the adoption of GLP by the findings produced. Business owners, decision-makers and even the government will benefit from this. The practitioners should concentrate on and address the impediments that have the greatest impact.

In order to establish sustainability between the economy and the environment, green logistics highlights numerous methods used to lessen the environmental issues associated with logistics operations, particularly those linked to GHGs, transportation, packaging and warehousing. Due to the manufacturing sector’s growing role in the Indian economy, research is needed to encourage the country’s manufacturing sector to adopt green logistics practises for the benefit of the larger ecological system.

Managerial Implication

In the study, tools for green logistics practises were created. Top management, the government and managers are all expected to use these tools to regularly measure and assess their performance across the various broad categories.

The studies and results of the green logistics practises on environmental and economic performance can also be seen and understood inside the Logistics Department of the Manufacturing Industry. Additionally, this might be beneficial for internal benchmarking.

Limitations and Future Directions

The following restrictions apply to the current study’s examination of green logistics issues and performance problems in a selected Indian manufacturing industry.

Based on the aforementioned restrictions, this work calls future researchers’ attention to the following issues.

Declaration of Conflicting Interests

The authors declared no potential conflicts of interest with respect to the research, authorship and/or publication of this article.

Funding

The authors received no financial support for the research, authorship and/or publication of this article.

Abubakar, T. (2014, November). A study of sustainability in the oil and gas supply chain. Lancashire Business School, 363. http://clok.uclan.ac.uk/11807/

Arockiaraj, B. A. (2017). A study on green practices management in petroleum logistics. International Journal of Economics and Management Studies, 4(7), 53–56. https://doi.org/10.14445/23939125/ijems-v4i7p112

Bartolini, M., Bottani, E., & Grosse, E. H. (2019). Green warehousing: Systematic literature review and bibliometric analysis. Journal of Cleaner Production, 226, 242–258. https://doi.org/10.1016/j.jclepro.2019.04.055

Carli, R., Dotoli, M., Digiesi, S., Facchini, F., & Mossa, G. (2020). Sustainable scheduling of material handling activities in labor-intensive warehouses: A decision and control model. Sustainability, 12(8), 3111. https://doi.org/10.3390/su12083111

Chhabra, D., Garg, S. K., & Singh, R. K. (2017). Analyzing alternatives for green logistics in an Indian automotive organization: A case study. Journal of Cleaner Production, 167, 962–969. https://doi.org/10.1016/j.jclepro.2017.02.158

Chang, T.-H., Tseng, J.-S., Hsieh, T.-H., Hsu, Y.-T., & Lu, Y.-C. (2018). Green transportation implementation through distance-based road pricing. Transportation Research. Part A, Policy and Practice, 111, 53–64. https://doi.org/10.1016/j.tra.2018.02.015

Chen, T. B., & Chai, L. T. (2010). Attitude towards environment and green products: Consumer perspectives. Management Science and Engineering, 4(2), 27–39.

Chen, X., Benjaafar, S., & Elomri, A. (2013). The carbon-constrained EOQ. Operations Research Letters, 41(2), 172–179. https://doi.org/10.1016/j.orl.2012.12.003

Chitra, K. (2007). In search of green consumer: A perceptual study. Journal of Services Research, 7(1), 173–191.

Frynas, J. G. (2010). Corporate social responsibility and societal governance: Lessons from transparency in the oil and gas sector. Journal of Business Ethics, 93(S2), 163–179. https://doi.org/10.1007/s10551-010-0559-1

García-Rodríguez, F. J., Castilla-Gutiérrez, C., & Bustos-Flores, C. (2013). Implementation of reverse logistics as a sustainable tool for raw material purchasing in developing countries: The case of Venezuela. International Journal of Production Economics, 141(2), 582–592. https://doi.org/10.1016/j.ijpe.2012.09.015

Ghosh, A., Jha, J. K., & Sarmah, S. P. (2016). Optimizing a two-echelon serial supply chain with different carbon policies. International Journal of Sustainable Engineering, 9(6), 363–377. https://doi.org/10.1080/19397038.2016.1195457

Ghosh, A., Jha, J. K., & Sarmah, S. P. (2017). Optimal lot-sizing under strict carbon cap policy considering stochastic demand. Applied Mathematical Modelling, 44, 688–704. https://doi.org/10.1016/j.apm.2017.02.037

Ghosh, A., Jha, J. K., & Sarmah, S. P. (2020). Production-inventory models considering different carbon policies: A review. International Journal of Productivity and Quality Management, 30(1), 1. https://doi.org/10.1504/ijpqm.2020.107280

Ghosh, A., Sarmah, S. P., & Jha, J. K. (2018). Collaborative model for a two-echelon supply chain with uncertain demand under carbon tax policy. Sadhana, 43(9). https://doi.org/10.1007/s12046-018-0899-6

Graedel, T. E. (2002). Material substitution: A resource supply perspective. Resources, Conservation, and Recycling, 34(2), 107–115. https://doi.org/10.1016/s0921-3449(01)00097-0

Hendrickson, C. T., Hovarth, A., Lave, L. B., & McMichael, F. C. (2001). Introduction to green design. https://p2infohouse.org/ref/21/20352.pdf

Hussain, D., Dzombak, D. A., Jaramillo, P., & Lowry, G. V. (2013). Comparative lifecycle inventory (LCI) of greenhouse gas (GHG) emissions of enhanced oil recovery (EOR) methods using different CO2 sources. International Journal of Greenhouse Gas Control, 16, 129–144. https://doi.org/10.1016/j.ijggc.2013.03.006

Indian Logistics Sector: Shining bright! (n.d.). India Brand Equity Foundation. https://www.ibef.org/blogs/indian-logistics-sector-shining-bright

Ishaswini, N., & Datta, S. K. (2011). Pro-environmental concern influencing green buying: A study of Indian consumers. International Journal of Business and Management, 6(6), 124–133.

Jiange, T. A. O. (2008). Researches on establishment model of green logistics system. Science Innovation Academic Frontier. https://www.scribd.com/document/45266315/Green-Logistics

Johansson, G., & Winroth, M. (2009). Lean vs green manufacturing: Similarities and differences [Paper presentation]. The 16th International Annual EurOMA Conference, Implementation Realizing Operations Management Knowledge, June 14–17, Goteborg, Sweden.

Jumadi, H., & Zailani, S. (2010). Integrating green innovations in logistics services towards logistics services sustainability: A conceptual paper. Environmental Research Journal, 4(4), 261–271. https://doi.org/10.3923/erj.2010.261.271

Karaman, A. S., Kilic, M., & Uyar, A. (2020). Green logistics performance and sustainability reporting practices of the logistics sector: The moderating effect of corporate governance. Journal of Cleaner Production, 258(120718), 120718. https://doi.org/10.1016/j.jclepro.2020.120718

Kim, S.-T., & Han, C.-H. (2011). Measuring environmental logistics practices. The Asian Journal of Shipping and Logistics, 27(2), 237–258. https://doi.org/10.1016/s2092-5212(11)80011-8

Kumar, P. D. (2011). Green marketing: A start to environmental safety. Advances in Management, 4(12), 59–61.

Kushwaha, S., Ghosh, A., & Rao, A. (2020). Collection activity channels selection in a reverse supply chain under a carbon cap-and-trade regulation. Journal of Cleaner Production, 260, 121034. https://doi.org/10.1016/j.jclepro.2020.121034

Labatt, S., & White, R. R. (Eds). (2012). Carbon finance: The financial implications of climate change. John Wiley & Sons, Inc.

Lee, S.-Y., & Klassen, R. D. (2008). Drivers and enablers that foster environmental management capabilities in small- and medium-sized suppliers in supply chains. Production and Operations Management, 17(6), 573–586. https://doi.org/10.3401/poms.1080.0063

Li, J., Pan, S.-Y., Kim, H., Linn, J. H., & Chiang, P.-C. (2015). Building green supply chains in eco-industrial parks towards a green economy: Barriers and strategies. Journal of Environmental Management, 162, 158–170. https://doi.org/10.1016/j.jenvman.2015.07.030

Li, A., Chen, Y., & Wang, D. (2020). An empirical study of the factors influencing the willingness to implement green coal logistics in China. Journal of Cleaner Production, 245(118932), 118932. https://doi.org/10.1016/j.jclepro.2019.118932

Liu, S., Zhang, Y., Liu, Y., Wang, L., & Vincent Wang, X. (2018). An “Internet of 188 Things” enabled dynamic optimization method for smart vehicles and logistics tasks. Journal of Cleaner Production, 215, 806. https://doi.org/10.1016/j.jclepro.2018.12.254.

Liu, S., Zhang, Y., Liu, Y., Wang, L., & Wang, X. V. (2019). An ‘Internet of Things’ enabled dynamic optimization method for smart vehicles and logistics tasks. Journal of Cleaner Production, 215, 806–820. https://doi.org/10.1016/j.jclepro.2018.12.254

Mariano, J. B., & Rovere, E. L. La. (2017). Petroleum engineering – downstream: Environmental impascts of the oil industry. Encyclopedia of Life Support Systems. https://www.eolss.net/sample-chapters/c08/e6-185-18.pdf

Marly, B. R., Levy, M., & Martinex, J. (2011). The public health implications of consumers’ environmental concern and their willingness to pay for an eco-friendly product. Journal of Consumers Affairs, 45(2), 329–343.

Martinsen, U., & Björklund, M. (2012). Matches and gaps in the green logistics market. International Journal of Physical Distribution & Logistics Management, 42(6), 562–583. https://doi.org/10.1108/09600031211250596

Moustafa, H., Youssef, A. M., Darwish, N. A., & Abou-Kandil, A. I. (2019). Ecofriendly polymer composites for green packaging: Future vision and challenges. Composites Part B: Engineering, 172, 16–25.

Murphy, P. R., & Poist, R. F. (2003). Green perspectives and practices: A ‘comparative logistics’ study. Supply Chain Management: An International Journal, 8(2), 122–131. https://doi.org/10.1108/13598540310468724

Mustapha, M. A., Manan, Z. A., & Wan Alwi, S. R. (2017). Sustainable green management system (SGMS) – An integrated approach towards organisational sustainability. Journal of Cleaner Production, 146, 158–172. https://doi.org/10.1016/j.jclepro.2016.06.033

O’Reilly, K. (2007). Summary and analysis of eye for transport’s worldwide survey: Green transportation & logistics. http://www.eft.com/green2008. Retrieved 27 September 2019, from http://722consulting.com/green_supply_chain_report.pdf

Rüdiger, D., Schön, A., & Dobers, K. (2016). Managing greenhouse gas emissions from warehousing and transshipment with environmental performance indicators. Transportation Research Procedia, 14, 886–895. https://doi.org/10.1016/j.trpro.2016.05.083

Salam, M. A. (2008). Green procurement adoption in manufacturing supply chain [Paper presentation]. The 9th Asia Pacific Industrial Engineering & Management Systems Conference, 3–5 December 2008, Indonesia, 1253–1260.

Sarkis, J., Zhu, Q., & Lai, K-H. (2011). An organizational theoretical review of green supply chain management literature. International Journal of Production Economics, 130(1), 1–15.

Sbihi, A., & Eglese, R. W. (2010). Combinatorial optimization and green logistics. Annals of Operations Research, 175(1), 159–175. https://doi.org/10.1007/s10479-009-0651-z

Seuring, S., & Müller, M. (2008). Core issues in sustainable supply chain management: A Delphi study. Business Strategy and the Environment, 17(8), 455–466. https://doi.org/10.1002/bse.607

Shalishali, M. K., Ho, J. C., Tseng, T., & Ang, D. S. (2009). Opportunities in green supply chain management. The Costal Business Journal, 8(1), 18–31.

Sherif, S. U., Asokan, P., Sasikumar, P., Mathiyazhagan, K., & Jerald, J. (2021). Integrated optimization of transportation, inventory and vehicle routing with simultaneous pickup and delivery in two-echelon green supply chain network. Journal of Cleaner Production, 287, 125434. https://doi.org/10.1016/j.jclepro.2020.125434

Srivastava, S. K. (2007). Green supply-chain management: A state-of-the-art literature review. International Journal of Management Reviews, 9(1), 53–80. https://doi.org/10.1111/j.1468-2370.2007.00202.x

Sureeyatanapas, P., Poophiukhok, P., & Pathumnakul, S. (2018). Green initiatives for logistics service providers: An investigation of antecedent factors and the contributions to corporate goals. Journal of Cleaner Production, 191, 1–14. https://doi.org/10.1016/j.jclepro.2018.04.206

Tian, G., Liu, X., Zhang, M., Yang, Y., Zhang, H., Lin, Y., Ma, F., Wang, X., Qu, T., & Li, Z. (2019). Selection of take-back pattern of vehicle reverse logistics in China via Grey-DEMATEL and Fuzzy-VIKOR combined method. Journal of Cleaner Production, 220, 1088–1100. https://doi.org/10.1016/j.jclepro.2019.01.086

United Nations. (n.d.). World population projected to reach 9.8 billion in 2050, and 11.2 billion in 2100 | United Nations. https://www.un.org/en/desa/world-population-projected-reach-98-billion-2050-and-112-billion-2100

Us Epa, O. (2021). Regulations for emissions from vehicles and engines. https://www.epa.gov/regulations-emissions-vehicles-and-engines

Wan Ahmad, W. N. K., Rezaei, J., Tavasszy, L. A., & de Brito, M. P. (2016). Commitment to and preparedness for sustainable supply chain management in the oil and gas industry. Journal of Environmental Management, 180, 202–213. https://doi.org/10.1016/j.jenvman.2016.04.056

Yergin, D. (2012). The quest: Energy, security and the remaking of the modern world. Penguin Books.

Zhang, W., Zhang, M., Zhang, W., Zhou, Q., & Zhang, X. (2020). What influences the effectiveness of green logistics policies? A grounded theory analysis. The Science of the Total Environment, 714(136731), 136731. https://doi.org/10.1016/j.scitotenv.2020.136731

Zhang, Y., & Liu, J. (2009). The establishment of green logistics system model. Science Innovation Academic Frontier. Retrieved, 5 September 2020, from http://www.bmtfi.net/en/search/index.php?key=The+establishment+of+Green+Logistics+system+model+&x=33&y=9

Zhang, G., & Zhao, Z. (2012). Green packaging management of logistics enterprises. Physics Procedia, 24, 900–905. https://doi.org/10.1016/j.phpro.2012.02.135

Zhu, Q., Sarkis, J., & Lai, K.-H. (2012). Green supply chain management innovation diffusion and its relationship to organizational improvement: An ecological modernization perspective. Journal of Engineering and Technology Management, 29(1), 168–185. https://doi.org/10.1016/j.jengtecman.2011.09.012